A material being developed for the automotive industry could be repurposed for capacitive desalination, making the process up to 40 times faster and less energy intensive.

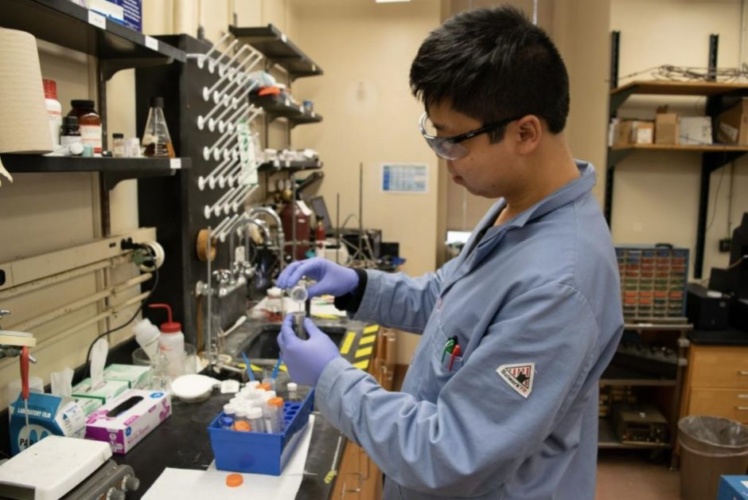

This is the claim of Guoliang “Greg” Liu, an assistant professor in the Department of Chemistry at Virginia Tech who has conducted extensive research into the design and synthesis of porous carbon fibres. The material is composed of long, fibrous strands of carbon with uniform mesopores of approximately 10nm.

According to Virginia Tech, Liu sees the primary application of his porous carbon fibres in the automotive industry, where similar materials are used as the external shells of some luxury cars. Now, Liu reports capacitive desalination as a new application for this material.

“Because of the high surface area of the porous carbon fibres, we can store a lot of ions,” Liu said in a statement. “Because of the interconnected porous network, the ion movement is very fast inside the pores.”

Reverse osmosis is the most well-known method of desalination, a process in which seawater is forced through a semi-permeable membrane to separate salts from water. Liu said the materials and process in reverse osmosis are relatively mature, and this energy-intensive process is efficient at treating large quantities of water. Capacitive desalination using porous carbon fibres requires much less energy for treating water with low salinity.

“The advantage of our process is that we can have much faster, much higher capacity, and more energy efficiency at this concentration range,” Liu said. “Under our experimental conditions of around 500 milligrams [of salt] per litre, it’s going to be way more expensive if you use other means because you’re trying to get a little bit of salt out of the water.”

Tianyu Liu, a postdoctoral research associate in the Liu Lab, served as the first author in an article detailing this work published in Science Advances.

He said the process sees two pieces of porous carbon fibres placed into a saline solution before a voltage is applied through them. This applied voltage created an electrostatic force that attracted the salt ions out of the water.

“Capacitive desalination treats the water using electrodes with high surface areas and electrical conductivity,” Tianyu Liu said. “The potential you apply reduces the ion concentration in water, and then you discharge the ions to regenerate the electrodes. These processes are repeatable with negligible loss of desalination capacity.”

Tianyu Liu noted that while this material has shown encouraging results, the research team has only shown a proof of concept for desalination. They are looking for partners to help scale up this research and design large-scale desalination cells.

No comments:

Post a Comment